Intralogistics and warehouse automation solution

Order picking system

Key words:

Order picking system

Related downloads :

- Description

- Specs

- Model

-

- Commodity name: Order picking system

- Category: Intralogistics and warehouse automation solution

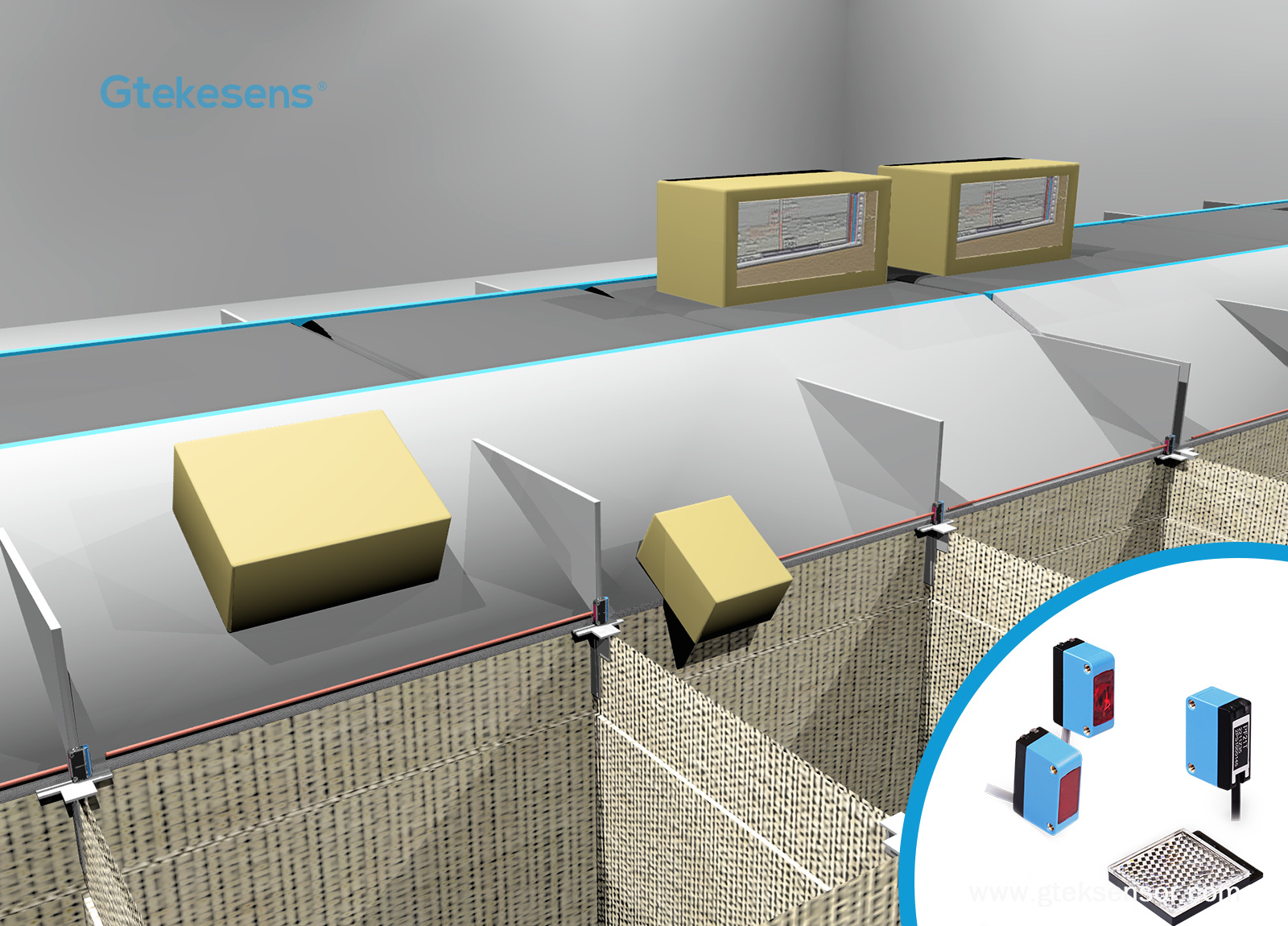

In e-commerce goods sorting, for orders with moderate order volume but high product overlap rate, the method of picking first, then sorting, and then secondary sorting can be adopted. Sowing wall, also named Put Wall , is a common secondary sorting method. In a fixed area, there are many seeding boxes, scan the wave number, and then scan the product code to automatically match the seeding boxes and corresponding quantities that need to be placed in the product.

Sensor solutions for E-commerce warehouse management system

In e-commerce goods sorting, for orders with moderate order volume but high product overlap rate, the method of picking first, then sorting, and then secondary sorting can be adopted.

Sowing wall, also named Put Wall , is a common secondary sorting method. In a fixed area, there are many seeding boxes, scan the wave number, and then scan the product code to automatically match the seeding boxes and corresponding quantities that need to be placed in the product.

(1) The Put Wall includes a rack and multiple material compartments arranged on the rack. The material compartments are used to store sorted goods, and the material compartments can be arranged in an array on the seeding rack.

Solutions:

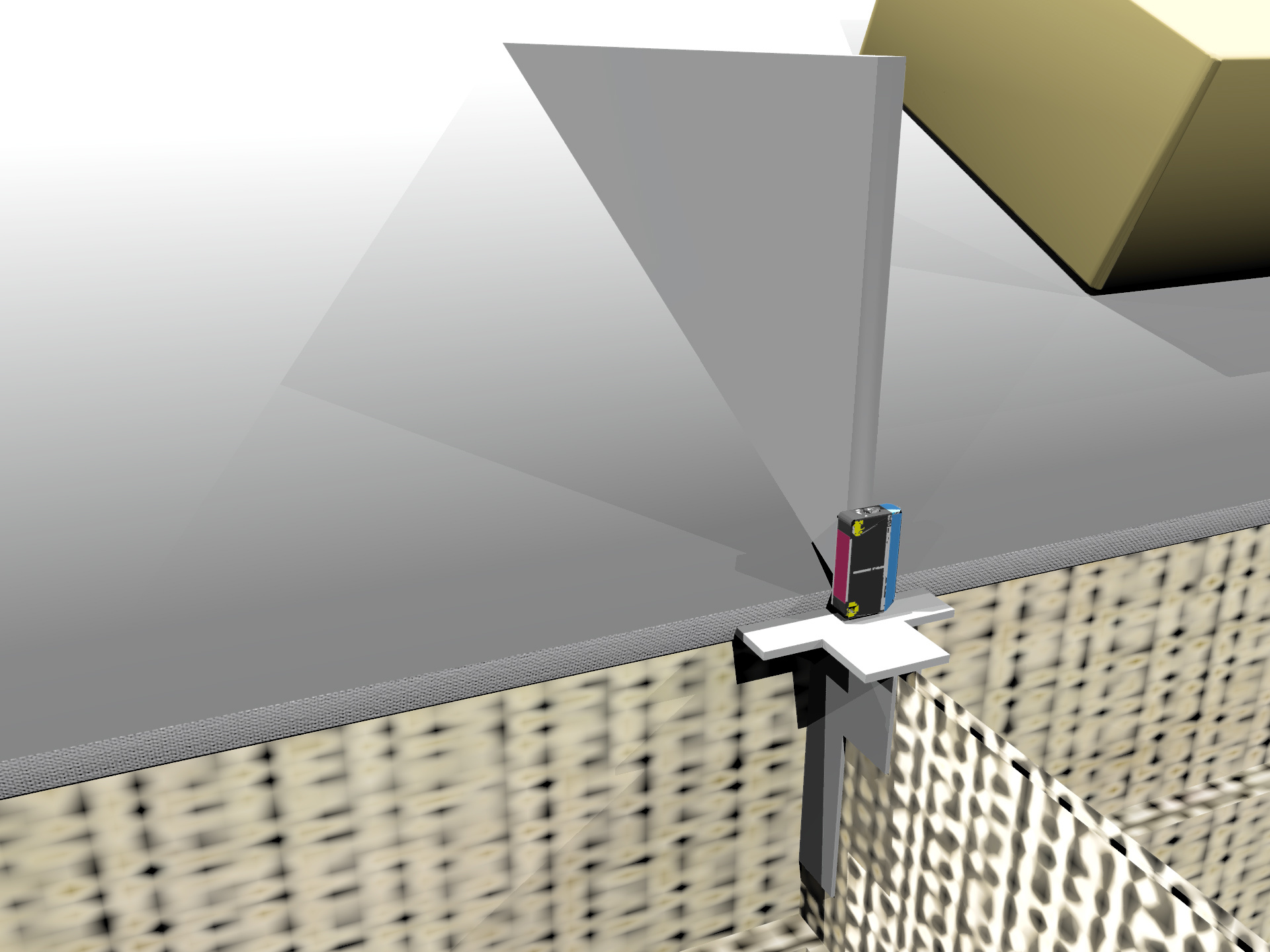

Placing infrared gratings on both sides of the material grid is currently a common method of material detection. The installation of infrared gratings is convenient, and the detection accuracy is high, greatly improving the efficiency of goods storage and sorting. LSE, LSM, and LSA series infrared region detection gratings provide customers with different options.

Related products:

· LSE infrared light barriers

· LSM light grids

· LSA multi-beam light curtains

(2) Express packages are transported along the conveyor, and packages from different destinations are transported to different grids and dropped into the corresponding sorting bags. When the number/weight of packages in this large bag reaches the specified range, the grid light will light up, reminding the staff to build and sew the package timely and to replace the large bags above in a timely manner. During this process, the information about building the package needs to be scanned by a spear to be transmitted to the sorting system.

Then how to detect the drop bags and judge the full state of the sorting bags?Solutions:

Bag rack type sorting is a common method of cross belt sorting. Installing PF21T or PF21B background suppression diffuse reflection sensors at the sorting port can perform real-time detection of bagged packages. Slim type LSEC grating products can also be used to achieve precise detection of small items, express letters, audio-visual products, and other flat objects, effectively avoiding missed inspections.Related products:

·LSEC infrared light barrier sensors

·PF21T through beam sensors

·PF21R mirror reflective photocell sensors

Related Product

Consult Now

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!